The Technology of Wire Wrapping

A wire wrapped connection is made by coiling the wire around the sharp corners of a terminal under mechanical tension. This method of connection was developed by Bell Telephone Laboratories, Western Electric Company.

|

|

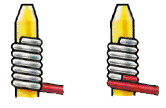

| Regular | Modified |

- A "Regular" bit wraps the bare wire around the terminal. A "Modified" bit wraps a portion of insulation around the terminal in addition to the bare wire. This greatly increases the ability to withstand vibration.

- A distinct advantage of wire wrapping is the ease with which a wire may be removed from a terminal to correct errors or modify wiring. An unwrap tool is slipped over the terminal, engaging the first turn of the connection. Rotating the tool, the connection is removed in seconds, without damage to the terminal.

- There is constant surveillance of manufacturing dimensions. Each wrapping bit is subjected to a series of "Qualification Tests". These consist of wrapping groups of wire on various types of test terminals. The wrapped wires are then subjected to a "Strip" test to determine adequate tightness. "Unwrap" tests are also performed to ensure against an "Over tight" wrap.

- Solid wire is used for wire wrapped connections. Copper is the most commonly used wire. Minimum elongation of 15% is required for 24 through 32 AWG; 20% for larger wire.

Wire Size Chart

| Bare Wire Diam. | AWG | SWG | |

|---|---|---|---|

| Inches | mm | (USA) | (GB) |

| .0403 | 1.022 | 18 | |

| .040 | 1.016 | 19 | |

| .036 | 0.914 | 19 | 20 |

| .032 | 0.813 | 20 | 21 |

| .028 | 0.711 | 21 | 22 |

| .0253 | 0.643 | 22 | |

| .024 | 0.61 | 23 | |

| .0226 | 0.574 | 23 | |

| .022 | 0.559 | 24 | |

| .0201 | 0.51 | 24 | |

| .020 | 0.508 | 25 | |

| .018 | 0.457 | 26 | |

| .0179 | 0.455 | 25 | |

| .0164 | 0.417 | 27 | |

| .0159 | 0.404 | 26 | |

| .0148 | 0.376 | 28 | |

| .0142 | 0.361 | 27 | |

| .0136 | 0.345 | 29 | |

| .0126 | 0.320 | 28 | |

| .0124 | 0.315 | 30 | |

| .0116 | 0.295 | 31 | |

| .0113 | 0.287 | 29 | |

| .0108 | 0.274 | 32 | |

| .0100 | 0.254 | 30 | 33 |

| .0092 | 0.234 | 34 | |

| .0089 | 0.226 | 31 | |

| .0084 | 0.213 | 35 | |

| .008 | 0.203 | 32 | |

Making a Wire Wrapped Connection

|

Step 1: Choose Bit & Sleeve for the pre-stripped wire size to be wrapped. Step 2: Insert the pre-stripped into wire slot. Step 3: Anchor the wire at the notch in the wrapping sleeve. Step 4: Insert the Terminal into the center hole of the wrapping bit. Step 5: Make a finished connection by starting the wrapping tool and rotating the wire around the terminal. |

"Strip" Force Chart*

| Wire Size | Min. number | Min. strip | |||

|---|---|---|---|---|---|

| AWG | Diam. | Diam. | of turns | force | |

| inch | mm | (Bare Wire) | lbs. | gms | |

| 16 | .051 | 1.30 | 4 | 15 | 6800 |

| 18 | .0403 | 1.00 | 4 | 15 | 6800 |

| 20 | .032 | 0.80 | 5 | 8 | 3600 |

| 22 | .0253 | 0.65 | 5 | 8 | 3600 |

| 24 | .0201 | 0.50 | 6 | 7 | 3200 |

| 26 | .0159 | 0.40 | 7 | 6 | 2700 |

| 28 | .0126 | 0.32 | 7 | 5 | 2200 |

| 30 | .0100 | 0.25 | 7 | 3.3 | 1500 |

Terminal Diagonal Chart

| In. mm |

.010 0.25 |

.015 0.38 |

.020 0.51 |

.025 0.64 |

.030 0.76 |

.035 0.89 |

.040 1.02 |

.045 1.14 |

.050 1.27 |

.055 1.40 |

.060 1.52 |

.065 1.65 |

.070 1.78 |

.075 1.91 |

.080 2.03 |

.085 2.16 |

.090 2.29 |

.095 2.41 |

.100 2.54 |

| .010 0.25 |

.014 0.36 |

.018 0.46 |

.022 0.56 |

.027 0.69 |

.032 0.81 |

.036 0.91 |

.041 1.04 |

.046 1.17 |

.051 1.30 |

.056 1.42 |

.061 1.55 |

.066 1.68 |

.071 1.80 |

.076 1.93 |

.081 2.06 |

.086 2.18 |

.091 2.31 |

.096 2.44 |

.101 2.57 |

| .015 0.38 |

.018 0.46 |

.021 0.53 |

.025 0.64 |

.029 0.74 |

.033 0.84 |

.038 0.97 |

.043 1.09 |

.047 1.19 |

.052 1.32 |

.057 1.45 |

.062 1.58 |

.067 1.70 |

.072 1.83 |

.077 1.96 |

.082 2.08 |

.087 2.21 |

.092 2.34 |

.097 2.46 |

.102 2.59 |

| .020 0.51 |

.022 0.56 |

.025 0.64 |

.028 0.71 |

.032 0.81 |

.036 0.91 |

.040 1.02 |

.045 1.14 |

.049 1.25 |

.053 1.35 |

.058 1.47 |

.063 1.60 |

.068 1.73 |

.073 1.85 |

.078 1.98 |

.083 2.11 |

.088 2.24 |

.093 2.36 |

.098 2.49 |

.103 2.62 |

| .025 0.64 |

.027 0.69 |

.029 0.74 |

.032 0.81 |

.035 0.89 |

.039 0.99 |

.043 1.09 |

.047 1.19 |

.050 1.27 |

.056 1.42 |

.060 1.52 |

.065 1.65 |

.069 1.75 |

.074 1.88 |

.079 2.01 |

.084 2.13 |

.089 2.26 |

.094 2.39 |

.099 2.52 |

.104 2.64 |

| .030 0.76 |

.032 0.81 |

.033 0.84 |

.036 0.91 |

.039 0.99 |

.042 1.07 |

.046 1.17 |

.050 1.27 |

.054 1.37 |

.058 1.47 |

.062 1.58 |

.067 1.70 |

.071 1.80 |

.076 1.93 |

.080 2.03 |

.085 2.16 |

.090 2.29 |

.095 2.41 |

.100 2.54 |

.105 2.67 |

| .035 0.89 |

.036 0.91 |

.038 0.97 |

.040 1.02 |

.043 1.09 |

.046 1.17 |

.049 1.25 |

.052 1.32 |

.056 1.42 |

.060 1.52 |

.064 1.63 |

.069 1.75 |

.073 1.85 |

.078 1.98 |

.082 2.08 |

.087 2.21 |

.091 2.31 |

.096 2.44 |

.101 2.57 |

.106 2.69 |

| .040 1.02 |

.041 1.04 |

.043 1.09 |

.045 1.14 |

.047 1.19 |

.050 1.27 |

.052 1.32 |

.056 1.42 |

.060 1.52 |

.064 1.63 |

.068 1.73 |

.072 1.83 |

.076 1.93 |

.080 2.03 |

.084 2.13 |

.089 2.26 |

.092 2.34 |

.097 2.46 |

.102 2.59 |

.107 2.72 |

| .045 1.14 |

.046 1.17 |

.047 1.19 |

.049 1.25 |

.050 1.27 |

.054 1.37 |

.056 1.42 |

.060 1.52 |

.063 1.60 |

.067 1.70 |

.071 1.80 |

.074 1.88 |

.078 1.98 |

.083 2.11 |

.087 2.21 |

.091 2.31 |

.096 2.44 |

.101 2.57 |

.105 2.67 |

.109 2.77 |

| .050 1.27 |

.051 1.30 |

.052 1.31 |

.053 1.35 |

.056 1.42 |

.058 1.47 |

.060 1.52 |

.064 1.63 |

.067 1.70 |

.071 1.80 |

.074 1.88 |

.078 1.98 |

.082 2.08 |

.086 2.18 |

.090 2.29 |

.094 2.39 |

.098 2.49 |

.103 2.62 |

.107 2.72 |

.111 2.82 |